Designation:

Designed for thermal neutralization of over 2300 types of waste in accordance with the FCCW 2014.

Applications:

Operating principles:

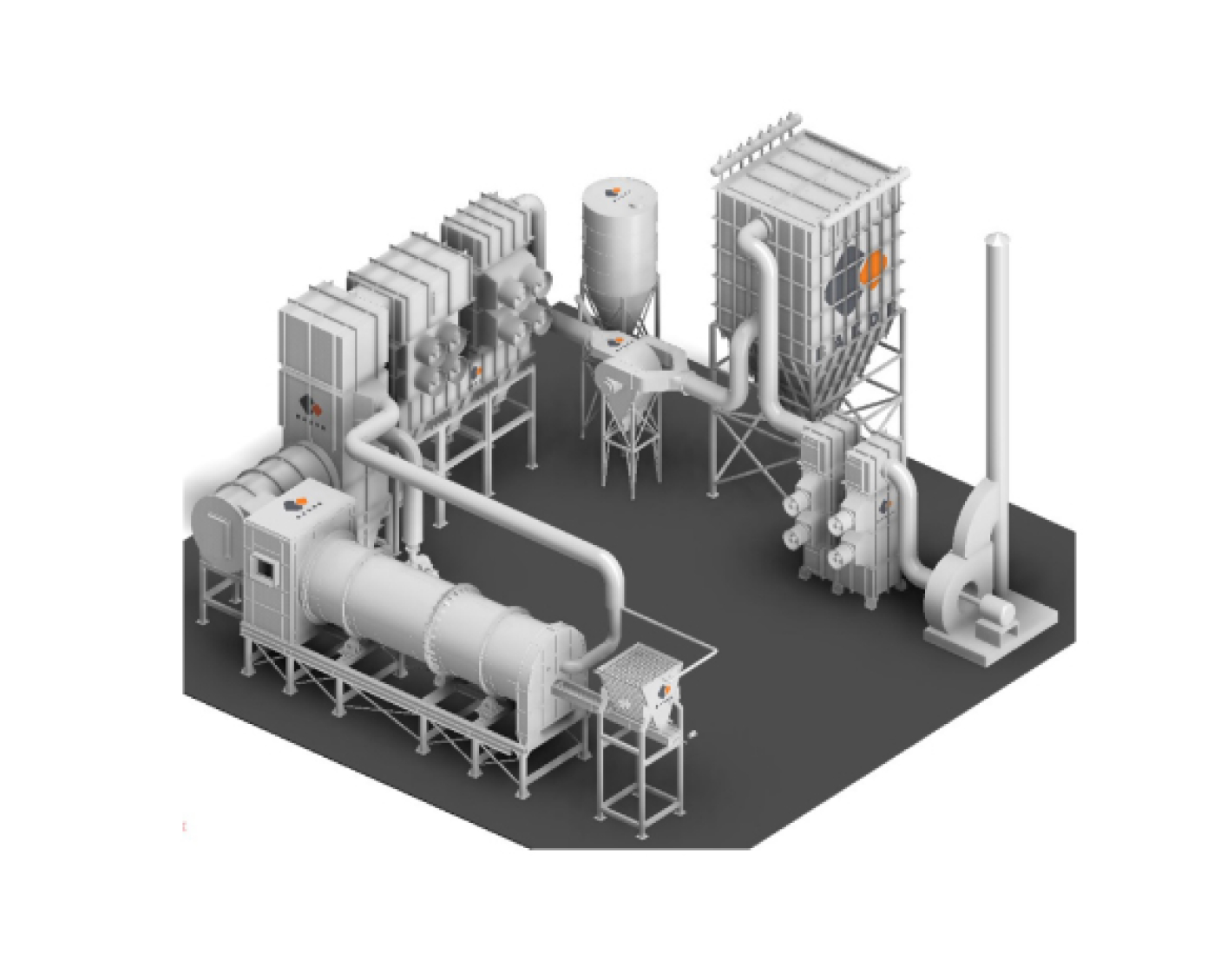

Thermal decontamination installation of solid and liquid waste, based on a chamber furnace with a liquid module. The thermal neutralization process takes place at a temperature of 800 to 950 degrees. The flue gases from the thermal destruction of waste go to the afterburning chamber, where at a temperature of 1200 degrees, the thermal decomposition of hazardous components takes place. Following the afterburning chamber, the gases are sent to the plate heat recuperator, where the flue gases are quenched and cooled to 350 degrees.

After the recuperator the flue gases are pre-cleaned in the centrifugal filter from coarse ash particles and sent to the ceramic filter for complex purification of flue gases from CO, NOx, SOx, HCL, HF, VOC and dioxins.

Main advantages:

Integrated gas purification system implemented in one apparatus — reactor — ceramic filter.

Technical characteristics of the incinerator UTO - 100

Item # | Parameter | Measurement unit | Value |

1 | Incinerator furnace volume | m3 | 0.33 |

2 | Flue gas afterburning chamber volume | m3 | 0.37 |

3 | Solid waste charging hatch size, L×W | м | 0.55×0.46 |

4 | Solid waste combustion rate | kg/h | 75 |

5 | Liquid waste combustion rate | kg/h | 25 |

6 | Specific consumption of diesel fuel | l/kg | 0.12-0.18 |

7 | Flue gas consumption at the installation outlet | nm3/h | 300 |

8 | Gas rarefaction in the incinerator furnace | Pa | 20-100 |

9 | Gas temperature in the incinerator furnace | °C | 800 - 950 |

10 | Gas temperature in the combustion chamber | °C | 1200 |

11 | Flue gases temperature at the ceramic filter inlet | °C | 300-450 |

12 | Flue gas temperature at the installation outlet | °C | 180 |

13 | Overall dimensions of the installation: L×W×H | м | 12×2.42×2.59 |

REFERENCE: Wastes to be thermally neutralized

Without alternative (only incineration): Medical wastes of classes B, C, partly D; secret archives, State Unsigned production etc.; pharmaceutical production wastes, drugs and substances; Waste from forensic medical services; corpses of infected and forcedly killed animals and birds; phyto- and veterinary confiscated goods, regulated articles; hair; chemical weapons; counterfeit, confiscated goods.

Alternative to removal to special landfills:

-Oil sludge, oil-contaminated soils, oil sorbents, etc., solvents: toluene, acetone, etc.; flare and vapor gas; gas condensates, ethylene glycols, gasoline, etc.; used motor oils, coolants; transformer oils containing supertoxicants: sovol, sovtol, etc.; toxic wastes with high content of chlorine, fluorine, phenol, iodine, bromine, etc. pesticides, herbicides and other agricultural pesticides; biological wastes: corpses of animals, birds, etc.; sewage sludge (cakes); oily rags; oil filters; old wooden railway sleepers impregnated with creosote and other compositions. Car tires and other rubber goods; car batteries, electronic and cable scrap, foiled paper, photo-materials.

Alternative to landfill disposal of solid waste or recycling:

Class A medical waste; organic “tailings” from solid waste and food waste sorting - Hazard Class IV; water-based drill cuttings; wood waste: container scrap, shortwalls, etc.

Wastes prohibited for thermal neutralization:

- Explosives, gunpowder, etc.; tightly sealed containers: paint cans, empty fire extinguishers, aerosol cans, etc.; mercury-containing wastes: daylight lamps, appliances; acid-containing wastes: electrolytes, batteries, etc. Freons: chloroform, carbon tetrachloride, etc.; persistent organic pollutants: aldrin, chlordane, dieldrin, endrin, heptachlor, hexachlorobenzene, mirex, toxaphene, etc. Waste containing more than 1% of supertoxicants.

Веб-форма не найдена.