Dusty flow through the inlet pipe enters the separating head of the apparatus. The flow in the apparatus is divided into two parts and enters the right and left separating channels. Changing the direction of flow in the curved channel leads to the appearance of centrifugal force acting on the flow and polydisperse dust particles, which are concentrated at the walls of half shells. The action of gravitational force on the solid particles provides their evacuation through the slot in the bottom cover to the hopper.

The number of half-pipes installed in series may be different. The more half shells installed in series, the higher is the efficiency of particulate matter recovery. At the same time the aerodynamic resistance of the apparatus grows. The cross section of the separation channel in the apparatus is calculated based on the flow rate of the flow being cleaned.

The devices can be assembled into modules of required capacity. The upper cover of the apparatus is equipped with hatches for periodic cleaning of the internal surfaces.

Multi-channel centrifugal dust collectors include units with the capacity from 1 to 50 thousand m3/h.Efficiency of gas purification:

From solid particles with a median diameter of more than 5 microns and a density of more than 2000 kg/m3 depending on the number of channels in the centrifugal filter can be tentatively estimated from the table:

Number of channels in a centrifugal filter | |||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

Collecting ratio. | |||||||

50 | 62 | 76 | 86 | 92 | 95 | 96 | 98 |

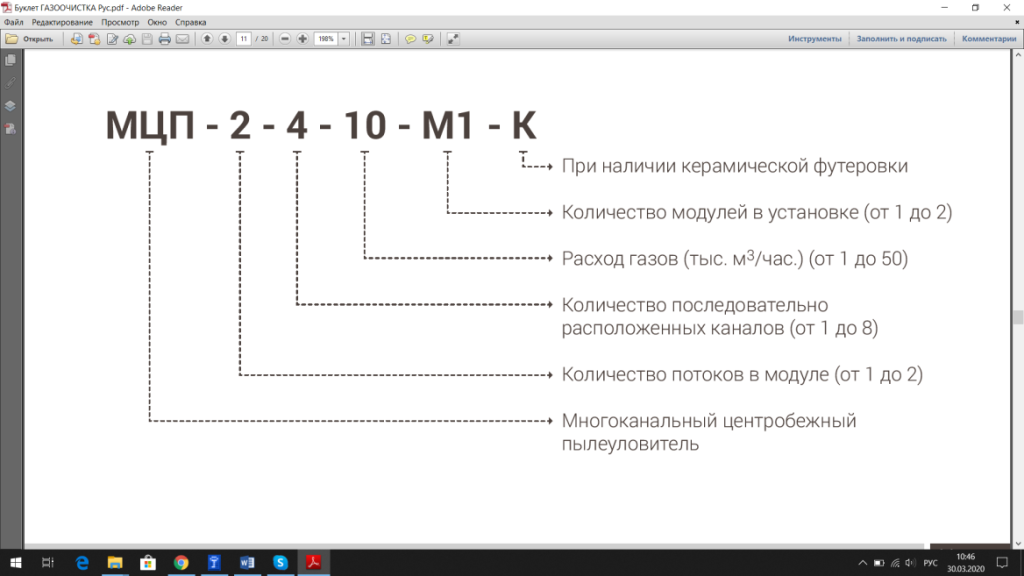

Labeling:

Options of equipment:

Material | ST-3, 09G2S, stainless steel. |

Lining | Internal surfaces are lined with ceramic shells (for high temperature applications and for purification of gases with abrasive particles). |

Support structures | According to the location of the installation |

Stairs - platforms | Step and vertical |

Gas duct | Gas lines, temperature compensators, supports |

Installation equipment with manholes | |

Smoke pumps, blowers | Centrifugal fan, exhauster. |

Dust discharging systems | Airlock, blinker, double blinker |

Sensors | Pressure, temperature, laser particle concentration meter. |

Control cabinet | With push-button control, touch screen display. |

Веб-форма не найдена.