Purpose:

For purification of gas-air flows from polydisperse dust with initial concentration of solid particles up to 100 g/m3 with temperature up to:

Applications:

Aspiration systems and bulk material transfer units, foundry yards, cement mills, clinker coolers, crushers, gas purification systems for drying drums, reactors, furnaces, solid fuel furnaces.

Main advantages:

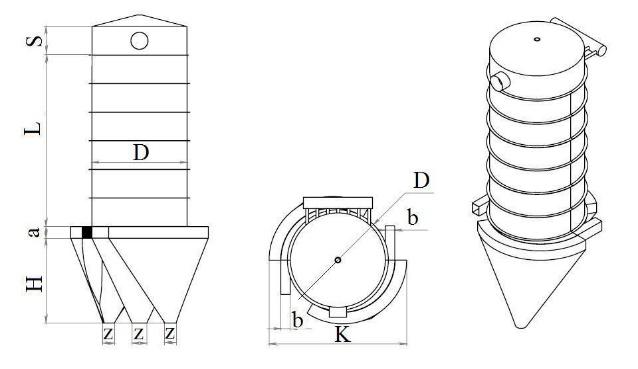

The cyclofilter operation is based on three-stage filtration.

First stage

- Centrifugal in a separation channel, from which the captured dust is immediately discharged into a separate hopper. Such pre-purification reduces the initial dustiness of the gas stream entering the filter element. Then the flow enters the second purification stage.

Second stage

- Centrifugal in a cylindrical chamber in which the filter elements are located. Then the flow enters the third stage of purification.

Third stage

- In the filter elements to capture fine dust particles.

Cyclofilter is a simple modular design consisting of interchangeable parts, so it is easy to configure.

The dust stream inlet can be bottom or top, one or two spigots. Two inlet pipes for the dusty flow inlet allow the cyclofilter to have 4-position flow rate control system in the first purification stage, maintaining its high efficiency by changing the flow rate of the dusty flow.

Purification Efficiency:

Guaranteed achievement of the requirements of sanitary norms.

Options of equipment:

Filter element | Woven on wire frame, ceramic |

Material of the cyclofilter | ST-3, 09G2S, stainless steel. |

Version of the cyclofilter | Under depression, under overpressure, explosion-proof. |

Gas treatment system | Gas-air cooler, atmospheric air suction valve, shutoff valve |

Support structures | According to the location of the installation |

Stairs - platforms | Step and vertical |

Gas duct | Gas lines, temperature compensators, supports |

Installation equipment with manholes | |

Smoke pumps, blowers | Centrifugal fan, exhauster. |

Dust discharging systems | Airlock, blinker, double blinker |

Sensors | Pressure, temperature, laser particle concentration meter. |

Control cabinet | With push-button control, touch screen display. |

Веб-форма не найдена.