Principle:

The structure of the ceramic high-temperature filter is similar to the structure and principle of operation of the bag filter. Dusty gas stream entering the unit for purification passes through the filter elements, on the surface of which is formed a dusty sediment, periodically regenerated by a impulse regeneration system.

There are two types of ceramics used as filtering elements in CIF ceramic filters:

Granular ceramic filter elements based on silicon carbide or aluminum oxide

Fibrous ceramic filtering elements based on silica fibers.

The ceramic filter elements are regenerated by an impulse regeneration system with compressed air or another inert gas. Regeneration is carried out automatically as the pressure drop in the filtration unit increases. The impulse regeneration system consists of a receiver with a purge and drying unit, solenoid valves, purge pipes with nozzles, and a control system. At typical specific gas load of 100 m3/m2*h and temperature of cleaned gases of 350-500°C aerodynamic resistance of CIF is 2000-2500 Pa. When opening the solenoid valve into the blowing pipe comes the flow with a pressure of 5-6 bar, coming out through a nozzle diameter of 7 mm it is directed to the open flange of the ceramic filter element while creating a flow rate of 100 - 120 m / s and a pressure of about 12000 Pa. This pressure is enough to clean the pores of the ceramic filter element and to destroy the filtration crust on the outside. Then the particles are deposited in the collecting hopper.

Filters can be assembled into modules of required capacity.

The filters are equipped with ceramic filter elements with diameters from 60 to 150 mm and lengths from 1000 mm to 6000 mm.

Applications:

Main advantages:

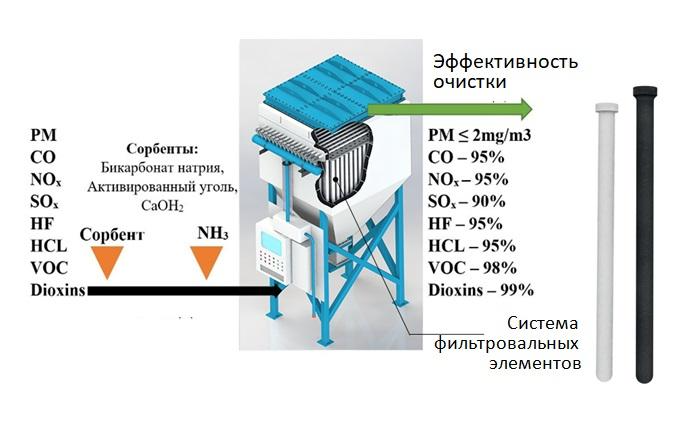

Comprehensive system of gas purification from CO, NOx, SOx, HCL, HF, VOC, dioxins is achieved through the use of:

Options of equipment:

Ceramic filter body material | ST-3, 09G2S, stainless steel. |

Version of filter | Under depression, under overpressure, explosion-proof, tent – shelter. |

Gas treatment system | Gas-air cooler, atmospheric air suction valve, shutoff valve |

Support structures | According to the location of the installation |

Stairs - platforms | Steps, vertical, manholes. |

Gas duct | Gas lines, temperature compensators, supports |

Smoke pumps, blowers | Centrifugal fan, exhauster. |

Dust discharging systems | Airlock, blinker, double blinker |

Chemical purification of gases | Device for dosing and feeding of sorbents |

Heat exchanger | Plate heat exchanger. |

Sensors | Pressure, temperature, laser particle concentration meter. |

Control cabinet | Push-button control, touch screen display. |

Веб-форма не найдена.