Industries:

High specific capacity

1.5-5 times higher than that of similar vacuum and press filters

Large filter area per unit of occupied space

Average concentrate moisture content is 8-10 %

Energy saving

Energy consumption is 6-10 times lower compared to vacuum fabric and press filters

Concentrate drying operation can be avoided

Minimization of investments in consumables, auxiliary equipment

No filter cake blowing

Reduction of operating costs

Reduction of filter element replacement costs

No abrasive wear of parts in the filtrate discharge system

Minimum operational and regular maintenance requirements

High corrosion resistance of the filter structure

Continuity of operation

Reduction of conveyor equipment costs

High filter availability — 98%

High capacity of the filtering area

Filtrate clarity and raw material saving

Lossless filtration of finely ground concentrates with 0.040mm size class content of up to 99%

High filtrate clarity: solids content of 0.001 to 0.005 g/l

Use of filtrate in closed-loop water-recycling systems and reduction of water consumption by 30 to 50%

Reduction of polymer flocculant consumption in thickeners

Environmental efficiency

No aerosol emissions in the filter operating area due to the avoidance of filter cake blowing

Clear filtrate that does not pollute production facilities and the environment.

Operational efficiency

Significant reduction of operating costs

Easy to assemble and maintain

Continuous operation and automation

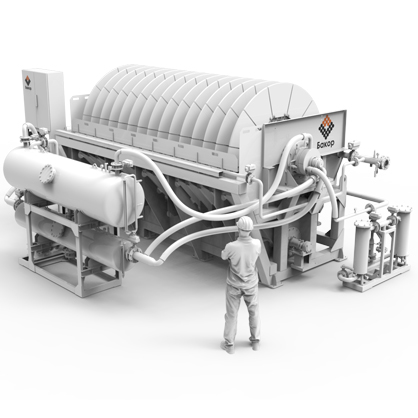

Compact and simple filter design featuring low specific content of metal, ease of installation, interchangeability of all filter elements

Patented plant shaft (drum) design ensures maximum consistency of operation

100% protection of the cake formation and dewatering zones from the ingress of backwash water or filtrate

Vacuum control in the cake formation and dewatering zones

Backwash pressure control

Bath and agitator design ensures uniform mixing of high-density concentrates

Specifications |

| CDF-0.5 | CDF-30 | CDF-90 | CDF-95 | CDF-108 | CDF-140 |

Filtering area | m2 | 0.5 | 30 | 90 | 95 | 108 | 140 |

Number of disks | ea. | 1 | 6 | 15 | 16 | 18 | 14 |

Filter dimensions |

|

|

|

|

|

|

|

Length | mm | 975 | 4,850 | 6,900 | 7,200 | 8,100 | 7,500 |

Width | mm | 995 | 3,910 | 3,400 | 3,400 | 3,400 | 4,200 |

Height | mm | 1,280 | 3,300 | 3,345 | 3,345 | 3,345 | 4,500 |

Installed power | kW | 5.0 | 40 | 55.0 | 55.0 | 55.0 | 75 |

Filter weight (dry) | t | 0.21 | 11.5 | 17.5 | 18.8 | 22.0 | 26.5 |

Веб-форма не найдена.