Main advantages compared to competitors:

- Sprayers with adjustable and easily cleaned nozzles (concentrate flushing system)

- The issue of insufficient stability of the frame lower belt has been solved by strengthening the load-bearing structure while preserving the same weight and dimensions

- Screw manual drum lifting to adjust the clearance between the drum and the bath

- Electric drive for magnetic system rotation. The electric drive facilitates magnetic system rotation and enables remote operation.

- Lining made of chemically/mechanically resistant material (polyurea)

- Separate lubrication system for all bearings (3 lubrication points) without separator shutdown installed on the separator NDE

- Easier replacement of drum bearings due to bearing installation in carriers

- Logistics related issues and significant growth of prices for foreign made separators

- Remotely operated separator controller (from a main control room)

- Ability to automate the operations of both one separator and the entire section of magnetic separators

- Magnetic separator digitalization by adding extra controls – pulp flow meter, flow density meter, etc. for process control and automatic adjustment

Specifications and standard sizes:

Main technical specifications

- Separator type – magnetic drum separator for wet

- milling of high magnetic ores

- Structural design – with a semi-counterflow bath

- Solids capacity – 250 to 350 m/h

- Feed capacity – 600 to 1,000 m3/h

- Drum working section diameter – 1,200 mm

- Drum working section length – 3,000 mm

- Drum rotation speed - 18-25 rpm

- Drum drive - N=9.2 kW n=1400 rpm, variable frequency

- Magnetic system rotation drive – N=0.25 kW n=1,400 rpm

- Overall dimensions for transport, max. (LxWxH) – 4,210x2,450x2,000 mm

- Overall operating dimensions, max. (LxWxH) – 4,450x2,450x2,000 mm

- Max. weight – 6,200 kg

Description

|

Values

|

MS 9025

|

MS 1230

|

MS 1520

|

MS 1530

|

Solids capacity, t/h

|

100-160

|

250-350

|

200-275

|

300-410

|

Rated drum electric motor power, kW

|

4.0

|

9.2

|

9.2

|

11.0

|

Drum working section size, mm

|

|

diameter

|

900

|

1,200

|

1,500

|

1,500

|

length

|

2,500

|

3,000

|

2,000

|

3,000

|

Max. weight, kg

|

3,800

|

6,200

|

5,700

|

8,400

|

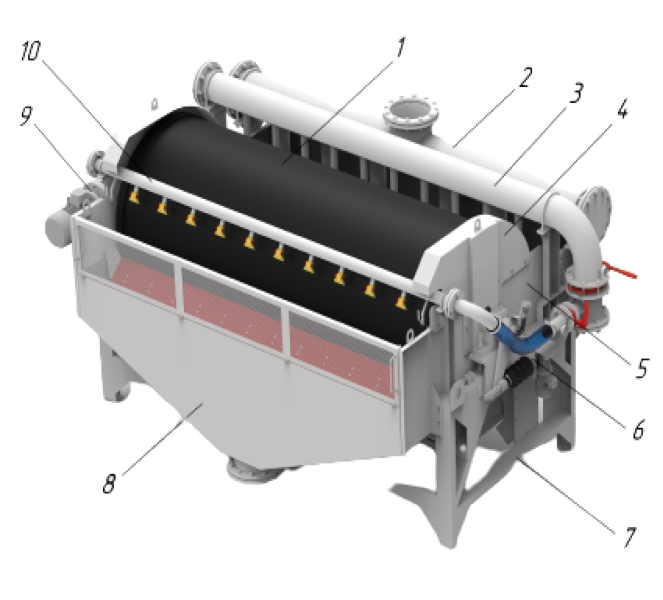

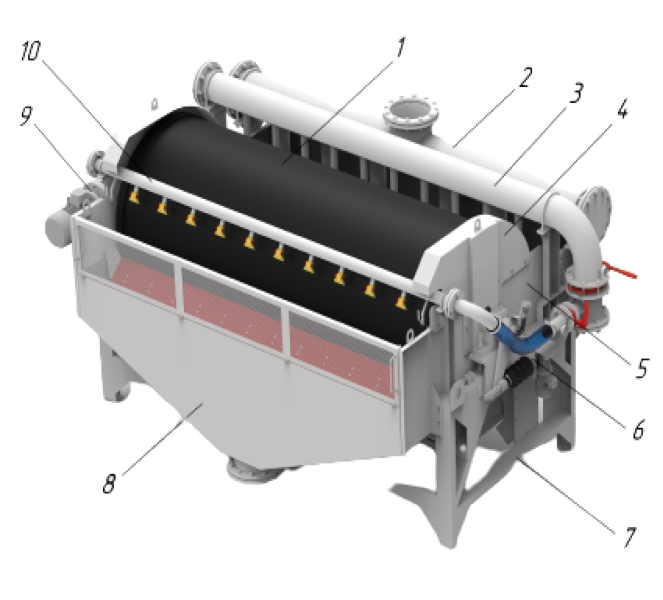

Scope of supply and principle of operation:

Scope of supply:

- Drum

- Loading manifold

- Feed dilution manifold

- Protective screen

- Bath

- Magnetic system rotation unit

- Frame

- Concentrate tray

- Drum drive gear motor

- Concentrate flushing system

Pulp enters the magnetic separator bath (5) through the loading manifold (2). Strongly magnetic minerals are attracted to the separator drum (1) by the magnetic field of the magnetic system. The separator drum rotates and moves magnetic minerals into the discharge zone – the concentrate tray (8). Non-magnetic minerals and accretions are removed from the bath via the discharge door in the bath bottom.

Защитный экран

|

Protective screen

|

Мотор-редуктор

|

Gear motor

|

Ванна (полупротивоточная)

|

Bath (semi-counterflow)

|

Лоток загрузочный

|

Loading tray

|

|

|

Барабан

|

Drum

|

Лоток концентрата

|

Concentrate tray

|

Система смыва концентрата

|

Concentrate flushing system

|

Коллектор разбавления питания

|

Feed dilution manifold

|

Загрузочный коллектор

|

Loading manifold

|

Защитный экран

|

Protective screen

|

Узел поворота магнитной системы

|

Magnetic system rotation unit

|

Рама

|

Frame

|

|

|

Патрубок подачи питания

|

Feed pipe

|

Коллектор подачи воды на разбавление питания

|

Feed dilution water supply manifold

|

Магнитная система

|

Magnetic system

|

Патрубок слива концентрата

|

Concentrate drain pipe

|

Патрубок слива хвостов

|

Tailings drain pipe

|

Переливной регулируемый борт концентрата

|

Overflow adjustable box for concentrate

|